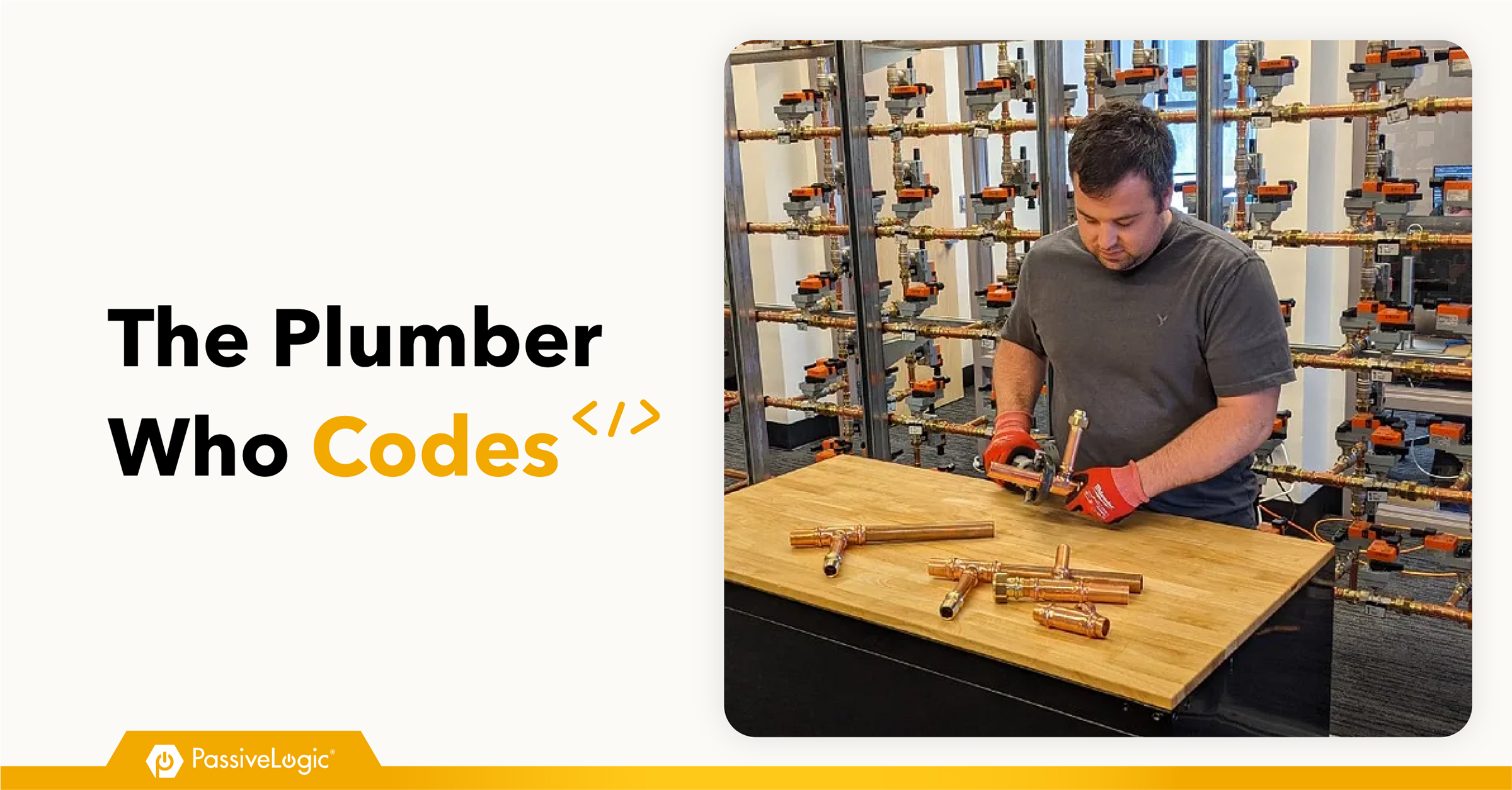

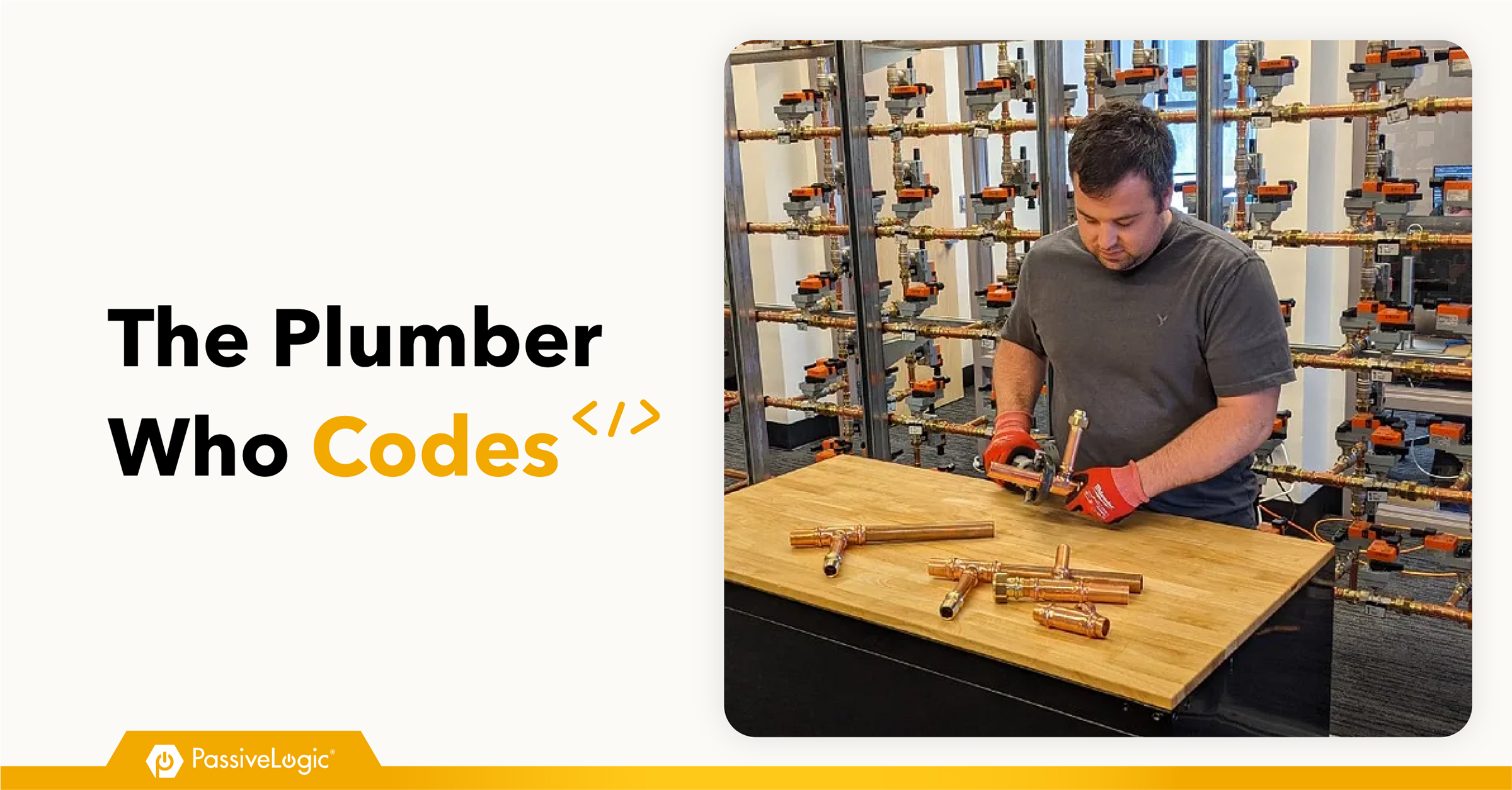

The Plumber Who Codes

Kepler Ridge is our lead Builder for The Wall — PassiveLogic’s Innovation Center under construction to demonstrate the Hive platform’s autonomous control capabilities. He spent the first few years of his career shifting between a path in plumbing vs one in software engineering — but here at PassiveLogic, he can do both.

Kepler turned to plumbing as a great way to earn money for school. He grew up near his grandpa’s farm and felt that plumbing was aligned to the family values he grew up with around good, honest hard work. This inherent work ethic was also a great fit for HVAC work. “With construction, you can’t miss deadlines and inspection timelines,” he said. “I’m a work horse…I don’t work 9–5, I can’t leave until the job is done.” He also has the capacity to stick with jobs that are repetitive and uncomfortable. “I remember drilling hole after hole in 10 degree weather in Park City, covered in sawdust. It sucks… but we gotta get the job done.”

Kepler completed a coding bootcamp program. Through personal connections Kepler learned of PassiveLogic and became interested in a company that is bringing AI and digital twins to the real-world physics of building control. “As someone who has worked in the field and worked with the equipment — I felt it would be amazing to be part of this company,” he said. He joined PassiveLogic to both build the Innovation Center and program the software managing the systems. He’s also starting back at school at night in the Fall to continue towards a degree in software engineering.

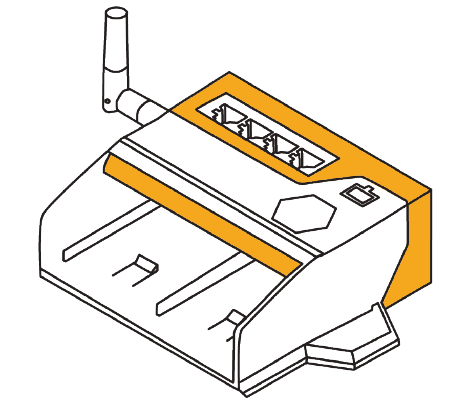

The PassiveLogic Innovation Center is a collaboration with multiple HVAC and plumbing providers, including Viega LLC. Viega is the leader in press technology, an innovative method to connect plumbing and pipefittings. All the copper fittings shown in the photo are Viega ProPress, which connects in just seconds without soldering or flame. “Using Viega ProPress was a big win for us,” said Kepler. “I’d say we saved over 40 hours compared to conventional sweat fittings. Plus, the lack of smoke and hot copper parts made the construction of this fixture in an occupied office far less invasive.”

Kepler started at PassiveLogic a few weeks ago, and the team floated a potential deadline of having the first phase of the Wall completed by the end of May. In true Kepler fashion, he worked long days, soldiered through, and had the job complete days before the deadline.